Synthetic affinity reagents offer new possibilities for future diagnostics

ARTICLE

Published in Laboratory News on the 24th April 2023

Fast and effective diagnostic testing is key to disease management but a challenge for antibody-based approaches. Animal/cell-free detection reagents present an opportunity for solutions at mass scale, explains Francesco Canfarotta.

The diagnostics industry relies on recognition. Every day we run thousands of tests that depend on the sensitive and specific recognition of chemical and biological substances. The results define what treatment people receive and, inevitably, affects their quality of life. Since the 1970s, the majority of diagnostic tests have relied on antibodies: biological affinity reagents that – via a suitable assay or sensor – can help us understand if someone has suffered a heart attack, is under the influence of drugs or is simply infected with the common cold. The promise of antibodies is strong, but the quality of each application varies to the point where sometimes it is hard to find an effective antibody in the first place. Development is an involved process, often requiring the use of animals, creating challenges around cost, time, and ethics. Even once an antibody has been generated, there is no guarantee that it has the required affinity or specificity to the target, or that it will work well in the chosen application.

But what if instead of depending upon biology, we could use chemistry? If we can make synthetic limbs for amputees and scaffolds to regenerate tissues, can we use chemistry to make synthetic affinity reagents?

The answer is: yes, we can. Polymer chemistry allows us to rationally design affinity reagents that can be scaled and deployed in different ways. Molecularly Imprinted Polymers, commonly termed nanoMIPs, are ‘smart’ polymers that are synthesised around a specific target such as small molecules, peptide sequence, or proteins. Their surface shape and chemistry match that of the target, acting as a synthetic affinity reagent which can then be incorporated into lateral flow devices or biosensors.

Recognition by design, not chance

Molecularly Imprinted Polymers have been researched for several years, but it is only more recently that the design and development methodology has advanced to a stage that makes the technology viable for diagnostic applications. The trouble with biological reagents, such as antibodies, is that we are completely dependent on an immune response for their production, and the language of antibodies is limited to ~20 amino acids. We are at the mercy of biology. Synthetic affinity reagents such as nanoMIPs, on the other hand, are rationally designed using hundreds of polymer building blocks. We have control over their chemistry, and with that comes control over the affinity reagent.

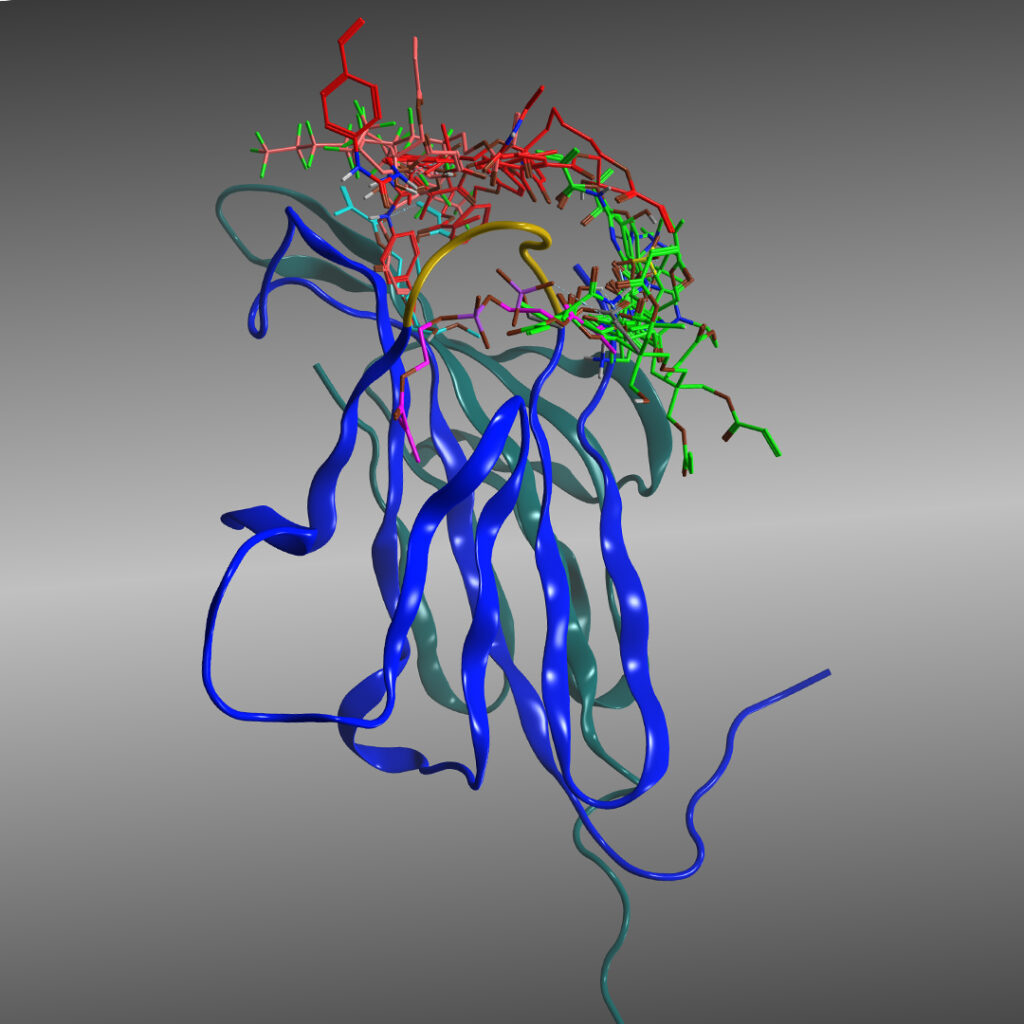

When it comes to developing a nanoMIP, in-silico molecular modelling allows us to build a 3D model of the diagnostic target or biomarker, and assess its structure (e.g. loops, beta sheets and alpha-helix structures) along with solvent accessibility. A specific region of the surface is then identified as the optimal place to build the nanoMIP around. Next, the building blocks of a nanoMIP, the functional monomers, are selected by the software. There are hundreds of monomers available when designing a synthetic affinity reagent, as opposed to around 20 amino acids when generating antibodies. This statistic alone highlights the potential of this technology in generating a high affinity reagent. When identifying monomers, the software assesses characteristics such as conformational structure, binding positions, and binding strength to identify the best monomer combinations to then take through to the laboratory.

Controlled manufacture with solid phase imprinting

Advances in imprinting technology have also been key in producing synthetic affinity reagents in an industrialised way, with the characteristics needed for diagnostic applications. The solid phase imprinting method, originally developed by Piltesky et al.[JB1] , enables the production of nanoMIPs with superior binding performance, and in a fashion that is fully scalable and reproducible. In the solid phase imprinting method, the target molecule is immobilised on a solid phase support such as micro-sized glass beads. A mixture of pre-selected monomers and cross linker are added, and naturally self-assemble around the target molecule via a range of interactions including electrostatic, hydrogen bonds, Van der Walls forces and hydrophobic interactions. A controlled polymerisation is initiated, and once complete, a series of temperature-controlled elution steps are used to selectively release the high affinity nanoMIPs, leaving the target behind, covalently immobilised on the solid phase support.

New diagnostic possibilities

One obvious advantage of synthetic affinity reagents is the elimination of animal-derived components within the industry. The chemical manufacturing process eliminates the need for the millions of sheep, rabbits and mice utilised in the current production of biological affinity reagents. Furthermore, unlike biological affinity reagents such as antibodies, chemically based affinity reagents are robust in many different environments, and their functionality is not impacted by extreme temperatures, pressures, and pH. Not only is this important for traditional point-of-care devices, but it also overcomes some of the challenges faced by the biosensors industry which, up until now, has seen limited commercial success outside of glucose monitoring. In fact, often biological affinity reagents denature when adhered to sensor electrodes, which has been a stumbling block for a wider range of applications. However, synthetic affinity reagents do not suffer with this challenge, and hence look set to be the key to unleashing the potential of the diagnostic sensors of the future. This will enable simplified multiplexing, and in-field testing where temperature control is limited.